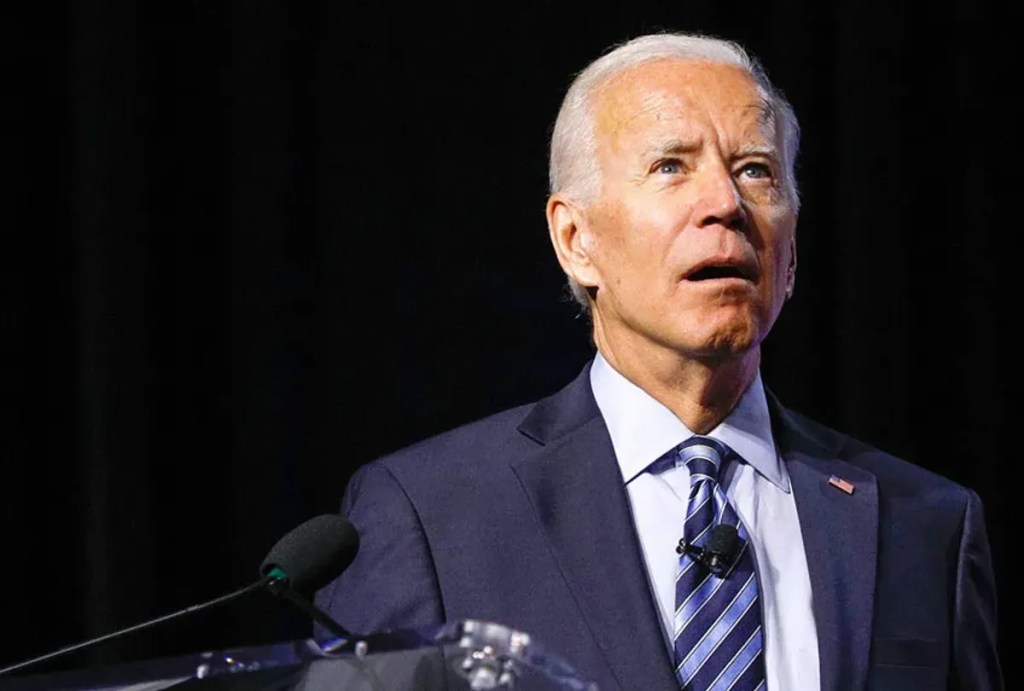

That fact checker is another example of biased reporting. Biden claimed an AR-15 bullet travels 5x faster than any other gun. Generally speaking this is not true and talking about the velocity of rounds can also be misleading. First a brief word about the firearm and the effects on velocity.

The ArmaLite AR-15 platform is a lightweight 22 caliber gas operated semi automatic rifle.designed in 1959. It was designed to be a smaller lighter less powerful version of AR-10 battle rifle created in 1956. It was designed for civilian use and was adapted into the M-16 for the Army in 1969. Eventually another shorter modified version called the M-4 carbine was put into service in the 1980’s. The AR-15 is designed to be easier to use then standard rifles. It is also MUCH less powerful than most standard rifles. The emphasis was being light and easy to use and the ammunition being light and small enough to be able to easily carry much more then you can with standard rifles. Now with the history lesson out of the way…

The length of the barrel of an AR-15 makes a HUGE difference in muzzle velocity, the speed at which the bullet exits the barrel. The most popular AR-15’s have shorter barrels of 16 inches or less. The longer a barrel is the higher the muzzle velocity. The .223 Remington cartridge or the 5.56mm NATO cartridge generally requires at least a 16 inch barrel to get up to proper velocity. So, shorter barrel versions will be slower. Generally speaking a 223 Rem gains or loses about 25.7 ft/s per inch of barrel. However this trade off is generally considered acceptable for use in close quarters situations. Muzzle velocities of firearms can range between 390 ft/s to as much as 5,600 ft/s with a full size AR-15 shooting a 55 grain .223 Remington averaging around 3,180 ft/s (for comparison a 115 grain 9x19mm Parabellum pistol round comes in at around 1135 ft/s). So just right there you can see the difference in velocity from a pistol to a rifle is less than 2.8x. One should not be surprised to see a difference like that between a pistol and a rifle which is nowhere near the 5x that Biden claimed. So basically the higher the muzzle velocity, the more energy it carries.

There is a lot that goes into the ballistics of bullets. The gun inself can drastically affect the ultimate ballistic energy of impact. Another huge affecting attribute is the bullet weight. If someone hits you with a 4 lb hammer it’s going to hurt a lot more than is they hit you with a 4 oz hammer. The 223 Remington cartridge comes with bullet weights ranging from 36 grain to 77 grain. The weight of the bullet has a huge effect on velocity as well. Out of a 24 inch barrel a 223 Rem with a 36 grain bullet will have a muzzle velocity of around 3,750 ft/s. A 77 grain bullet will have a muzzle velocity of only 2,750 ft/s. The higher the weight in grain the more energy it carries.

Now when you combine the 2 variables of barrel length and bullet weight, you end up with a range of ballistic energies imparted on the target. At 100 yards a 77 grain 223 out of a 24 inch barrel will have a ballistic energy of about 1005 ft-lb. A 36 grain 223 out of a 10 inch barrel will have a ballistic energy of only 687 ft-lb.

The most popular configurations are a 16 inch barrel firing a 55 grain bullet with a ballistic energy at 100 yards of about 851 ft-lb or a 10 inch barrel shooting 77 grain bullet at 50 yards with about 817 ft-lb of kinetic energy. And as a little bit a trivia, it generally takes over 1,000 ft-lb of kinetic energy to kill a deer. No kevlar vest needed for Bambi with the typical AR-15.

But he just had to go on and throw his two cents in about how the AR-15 is so dangerous and used in so many mass shootings…. A whopping 3% of murders according to the FBI in 2020.